| Houses consume many natural resources in large quantities. It is important therefore to use more environmentally friendly materials and to use them effectively. New Ceramic, developed by Misawa Homes for its HYBRID ceramic homes, is made mainly from silica sand and limestone, both in abundant supply. Our New Ceramic features many functional characteristics necessary for houses. Its durability and superior thermal insulation characteristics make it an ideal material for use in home construction. |

Demolded ceramic wall panel |

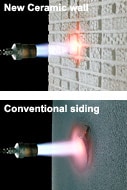

Exterior wall heat tests |

Panels made of New Ceramic make excellent exterior walls. New Ceramic itself is highly durable, with rust-proof double steel meshes inside the panels lending exceptional strength. The panels can withstand heat up to 1,000C for an hour without any adverse effect on the interior.

New Ceramic provides 12 times the insulation value of conventional concrete and also boasts high sound insulation. The New Ceramic wall system is made up of ceramic panel, glass wool, air layer, and gypsum board into a thickness of 234mm. This construction yields a very high insulation value that helps make a home’s interior cooler in summer and warmer in winter, thus lowering the electricity bill. Also, its high humidity adjustment performance deters water condensation, which can prolong the life of houses.

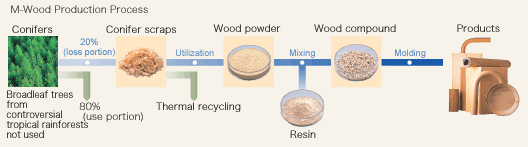

Misawa Homes has developed such innovative products as M-Wood, which uses recycled materials. The company is strongly committed to continuing to develop and procure environmentally friendly materials and equipment. For example, “ECOCUTE,” a heat pump hot water system, uses CO2 as refrigerant, drastically reducing CO2 emissions as compared with combustion water heaters. Also, diatomaceous earth cloth is friendly to the environment with its ability to absorb and release humidity.

Environmentally Friendly Materials and Equipment

| Energy | Thermo Bath, ECOCUTE, heat pump, induction-heating stove |

|---|---|

| Resources | M-Wood, M-Wood2, New Ceramic, recycled tiles |

| Indoor environment | Zero-formaldehyde adhesive, diatomaceous earth |

| Others | Rain water storage system, 24-h central ventilation system, roof greening (planting or placing small shrubs on rooftops) |

M-Wood interiors |

“ECOCUTE” system |

Diatomaceous earth cloth |

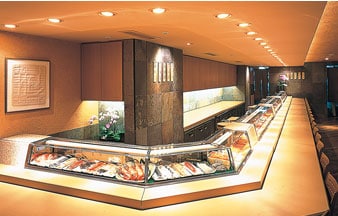

The Misawa Homes Group recognizes the value of forest resources and that homebuilding can consume many trees. To reduce that consumption and comply with the ideals of “resource conservation,” “alternative materials,” and “recycling,” we have developed an entirely new wood-based material, “M-Wood.” The main component of M-Wood is the scrap generated when sawing and machining lumber. The resulting material retains the look and feel of wood; is more weather resistant; and does not warp, twist, or shrink. M-Wood products are ideal for use in damp areas such as bathrooms and sashes. It can be molded into many different sizes and shapes and can be used to coordinate all home interiors. It can also be used in barrier-free homes which may require continuous handrails without joints and stair steps with uneven surfaces. These features of M-Wood are now finding new applications in hotel bathrooms, store interiors, speaker boxes, and even train interiors. In cooperation with Japan Railway, we developed interiors using M-Wood for its “Sunrise Express” sleeper train in 1998. The warmth and softness of the material, which provides passengers with an ease of mind, has won the Good Design Gold Award in the transportation category.

M-Wood interiors |

M-Wood bathroom |

M-Wood has been awarded an Environment Minister certification in accordance with Waste Disposal Law, which authorizes us to collect M-Wood waste ourselves without a waste disposal license. This makes it possible for us not only to recycle materials more efficiently but also to reduce CO2 emissions because both inbound and outbound trucks are carrying loads.We are expanding collection areas and increasing collection quantities so that we can establish a complete recycle system to achieve “zero M-Wood waste.”

M-Wood sushi counter

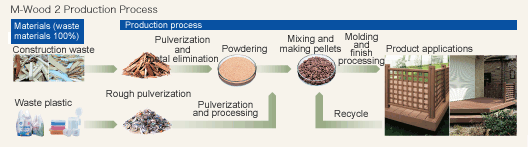

M-Wood2 is a 100% recycled material using wood and plastic waste. Developed in pursuit of full recycling of materials by the M-Wood technology, M-Wood2 can be widely used as a material for decks, gates, fences, and many other structures. In fiscal 2005, our environmentally friendly material stepped into the limelight. The Central Japan International Airport, which was designed to be environmentally friendly and put into service early in 2005, adopted M-Wood for its Sky Deck covering an area of about 7,000m².

M-Wood2 roof deck of a department store in Tokyo |

The 2005 World Expo, Aichi, which was also called an “environmental expo,” used M-Wood2 for the deck at the Global Loop facility and the floor area of the West Entrance at its main Nagakute Site for a combined total area of about 19,000m². M-Wood2 was chosen by them because of its high durability and low environmental burden. |

Sky Deck (Photo: Central Japan International Airport Co., Ltd.) |

|

M-Wood2 can reduce the lifecycle environmental burden of all products made using it. When the lifecycle is divided into resource, product, and recycle phases, they can be characterized in terms of reduction of environmental burden as shown below. M-Wood2 has received the first Building Center of Japan’s AIBT-6 approval, a certification for recycled organic building materials that can contribute to a reduction in environmental burden. It has also obtained the Eco Mark from the Japan Environment Association as a material which protects Earth and the environment. The Ministry of Land, Infrastructure, and Transport has approved M-Wood2 as a superior material for use in the private sector and it is registered on its NETIS (New Technology Information System) program.

| 1. Resource phase | 2. Production phase | 3. Recycle phase |

|---|---|---|

| The main raw materials of M-Wood2 are waste wood generated at construction sites and waste plastic. No new raw materials are required to produce new M-Wood2 products, and thus no waste is produced. | The production of M-Wood2 products does not generate any harmful substances, and although it consumes electricity, the product itself lowers CO2 emissions. | Scrap material generated when M-Wood2 is fabricated into products can be recycled. Also, M-Wood2 products themselves can be collected, pulverized, and re-used as raw material many times, thus lessening the burden on the environment. |