Finland, a country that is committed to wise management of its forests and that has extensive reforestation programs, is a major supplier of lumber to Misawa Homes. Because Finland allows only 75% of its annual fores growth to be consumed, its forest resources are managed and protected so that they are increasing. In 1995, Misawa Homes built a lumber mill in Finland to make full use of wood products procured from that country. The majority of wood is machined into materials for housing components and furniture, but we fully utilize the entire tree. Bark becomes fuel for power generation, and wood chips are reduced to pulp.

In May 2006, Misawa Homes of Finland received a PEFC-CoC. PEFC (Programme for the Endorsement of Forest Certification) is an international organization that promotes sustainable forest management through third-party certification.

The company has also built a lumber mill in China, which is rapidly assuming a leadership role in forestation and reforestation programs. The plant, certified by Japan Agricultural Standards (JAS), commenced operation in July 2002 to produce laminated veneer lumber (LVL), milled from poplar trees that grow rapidly and are thus very environmentally friendly as a rapidly renewable resource. In early 2006, this plant developed “Hybrid LVL” using forest resources there. This program has also been certified by JAS.

|

|

|

Lumber mill in China |

PEFC-CoC certificate |

|

|

Lumber mill in Finland |

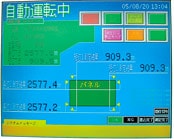

| All Misawa Homes factories operate in accordance with the unique MPS (Misawa Profit System) to promote further industrialization of housing. Our philosophy of “producing many items in small quantities” aims, in principle, to standardize housing components, develop specialized production lines, and deliver construction materials and components to construction sites only when needed. This enables us to conserve energy in the production stage while improving quality and production efficiency. The Misawa Profit System has lowered the environmental burden of production to one-tenth its previous level. |

Automatic panel dimension monitoring system |

To further promote industrialization, Misawa Homes has developed sub-assembly and mini-assembly units used in building wooden homes. Sub-assembly units make construction of a house easier as they come in large panel units equipped with such items as window sashes. Mini-assembly panel units are delivered in smaller sizes to make the construction of a house on a restricted site in congested urban areas easier. Together, these methods reduce construction waste and noise and lower the prices of Misawa-built homes.

In creating Misawa HYBRID ceramic homes, we produce capsule units equipped with such items as walls, equipment, and facilities at the factory and deliver those units to construction sites for erection. These homes are 90% completed at the factory, with only the remaining 10% of erection labor and costs required at the construction site.

On-line installation of anti-termite sheet |

Exterior wall assembly |

Erection of a ceramic home |

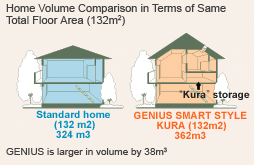

| Conserving resources in the production stage is only part of the story, however. Misawa Homes also strives to use fewer material resources for the houses themselves. Many models having large storage areas called Kura. The “GENIUS SMART STYLE Kura” is one of these models. Of its total floor area, storage areas account for 37%, a sharp contrast to the 9% for average homes. The home also has a steeper gable roof so it can have more volume on the same footprint compared with ordinary houses and require fewer resources to build. Our cost-estimation system also helps conserve resources. |

Kura allows larger space to family life |

GENIUS SMART STYLE KURA |

|

Misawa is also a major player in the rapidly expanding home-renovation business. Misawa Homes Group’s home-remodeling services enhance asset values by upgrading the performance, function, and design of existing homes, enabling people to live in them longer and thereby conserve the resources to replace them.

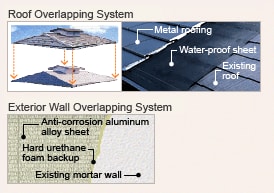

The roof-renovation system called “Overlapping System” is unique to Misawa Homes. New roofing and peripheral exterior siding materials are placed on top of the existing roof. This method does not harm the structure, produces less construction waste, and requires less time for renovation. The overlapped roof looks better and provides superior insulation.

The “Hanare” housing unit can be used for a SOHO office, study, or home theater. These compact units can be built adjacent to and within the property boundaries of existing homes without generating construction waste in remodeling.

|

Renovated kitchen |

Interior items can be replaced with environmentally friendly M-Wood products. A wide range of “put on” type products such as kitchen units are also available. For those houses without termite-prevention sheets, we provide an extended 10-year guarantee with the installation of our “pollution-free anti-termite sheets.” Misawa Homes extensive product line and range of services won the company a Good Design Award in 2001, the first in the home-renovation industry.