CONTENTS

Misawa Homes has announced a “New Environment Declaration” in 1997 as an environmental initiative. Since then, based on that declaration, we have developed a variety of environmental activities.

Misawa Homes Co., Ltd. formulated Environmental Policies based on the Environmental Declaration of the Misawa Homes Group, and uses them to confirm and observe laws and regulations, develop environmentally conscious products, engage in environmental conservation activities for Misawa Homes no Mori—community centers for environmental events and efforts—and implement many other business activities. Additionally, we confirm and provide guidance on aspects such as the operation status of the Environmental Management System to divisions engaged in environmental activities, and deliver reports on the matters to management.

Misawa Homes Co., Ltd. implements business activities based on the following policies and in consideration of the environmental philosophy of the Misawa Homes Group.

Ever since the Misawa Homes Group was founded, we have strived to develop the most advanced technologies based on original ideas, always aiming at making world-first, Japan-first, or industry-first breakthroughs.In a wide range of business activities, we have deployed these technologies to solve social and environmental problems.

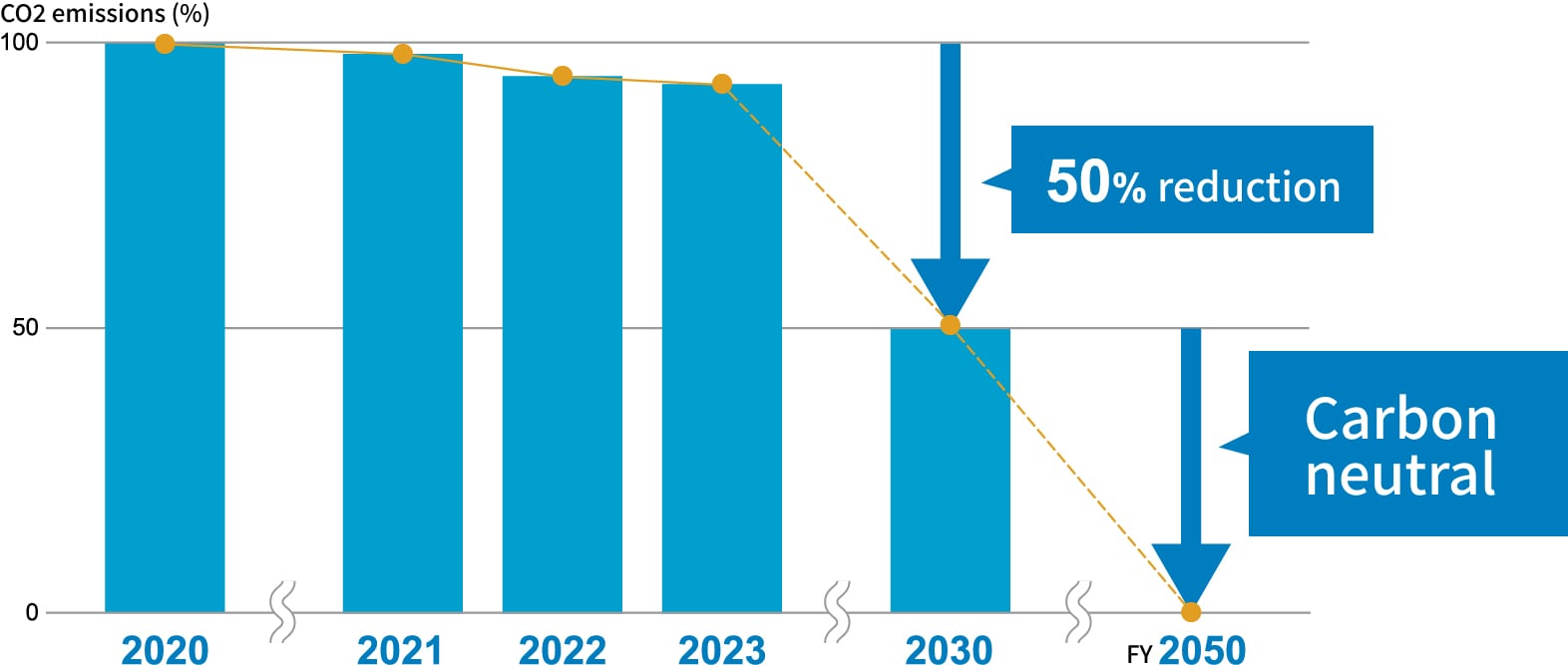

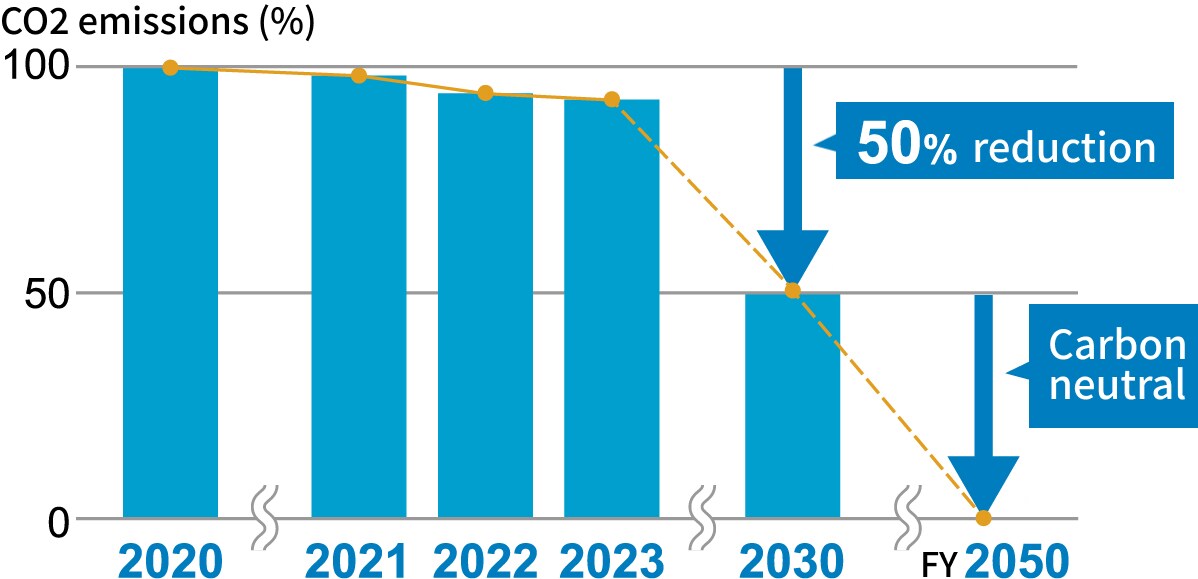

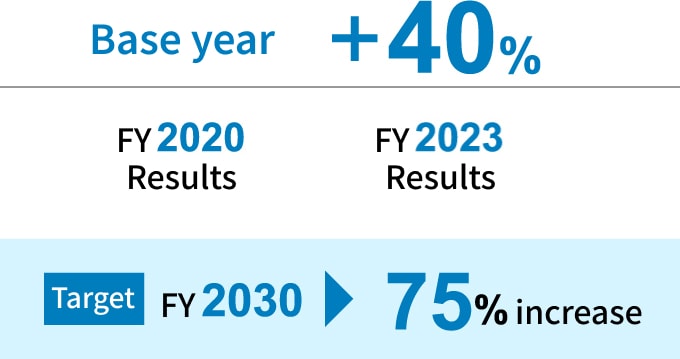

The Japanese government declared in October 2020 that it would aim to become carbon neutral by 2050. In Japan, the consumer sector*1 accounts for about 30% of final energy consumption, raising the need and expectation for the housing industry to reduce consumption from both hardware and software perspectives. The Misawa Homes Group promotes CO2 emission reduction through various business activities to achieve carbon neutrality by 2050 via housing stock business, community development business, and the promotion of ZEH*2 and LCCM®*3 in new-house business.

*1 Including the household and business sectors

*2 Zero Energy House

*3 Life Cycle Carbon Minus housing LCCM is a registered trademark of the Institute for Built Environment and Carbon Neutral for SDGs (IBECs).

It refers to a decarbonized house that achieves negative CO2 emissions across the entire life cycle from construction, to occupancy, to demolition.

*1 Including the household and business sectors

*2 Zero Energy House

*3 Life Cycle Carbon Minus housing LCCM is a registered trademark of the Institute for Built Environment and Carbon Neutral for SDGs (IBECs).

It refers to a decarbonized house that achieves negative CO2 emissions across the entire life cycle from construction, to occupancy, to demolition.

Image of Carbon Neutrality Achievement (Excluding Overseas and Community Development Businesses)

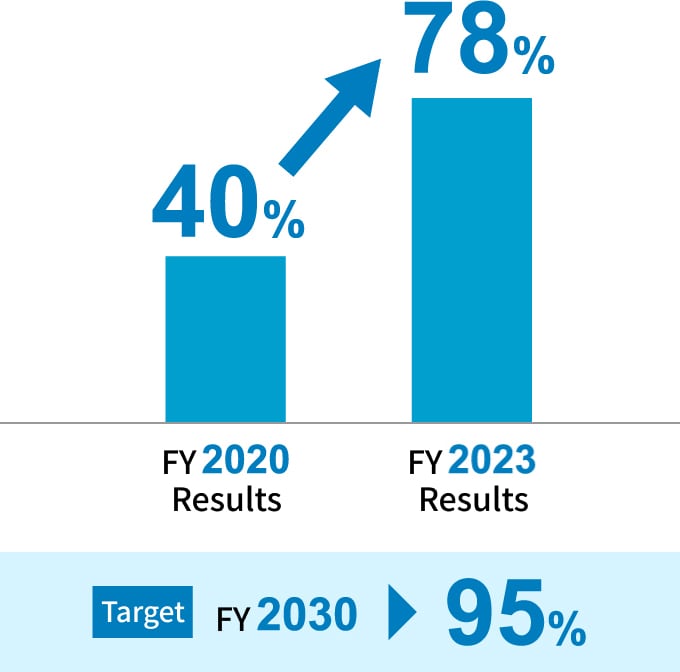

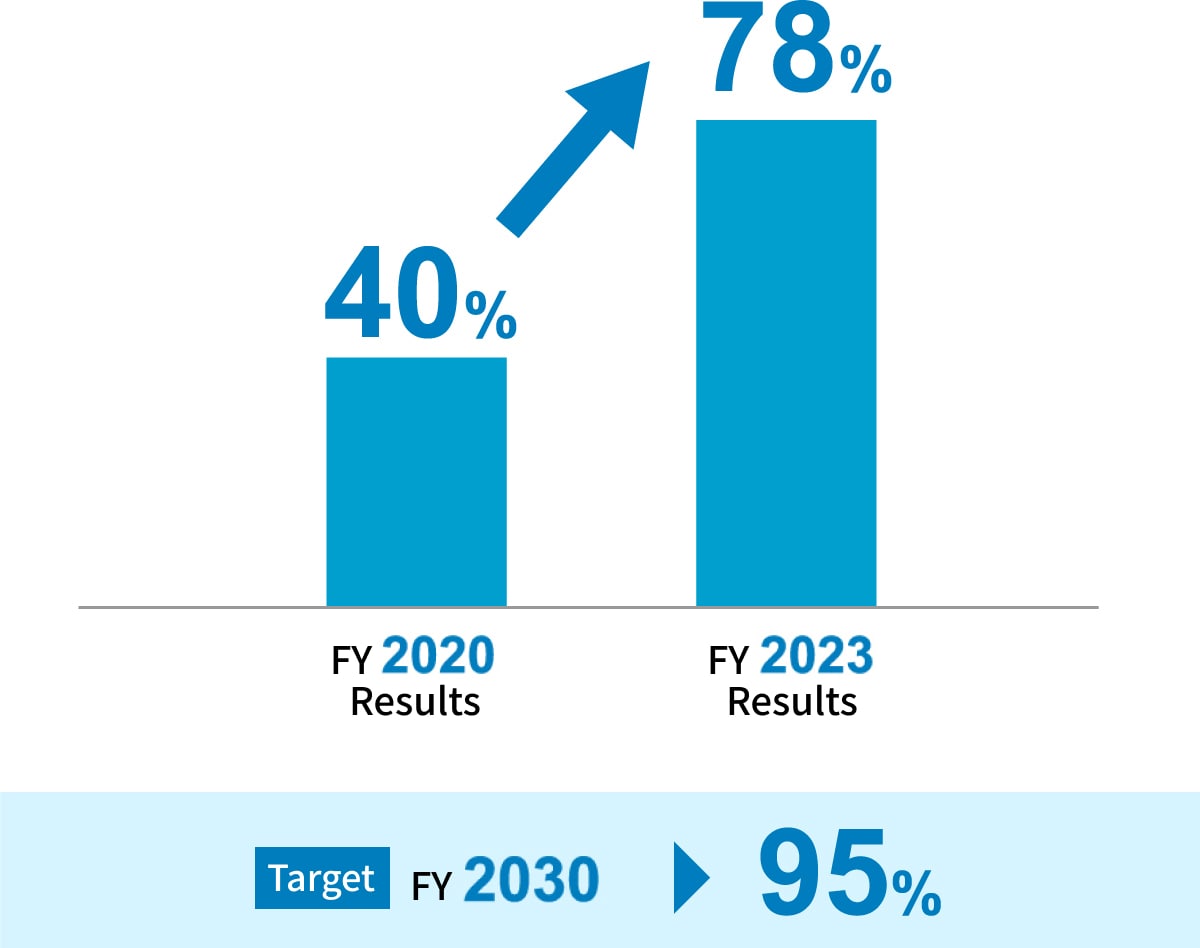

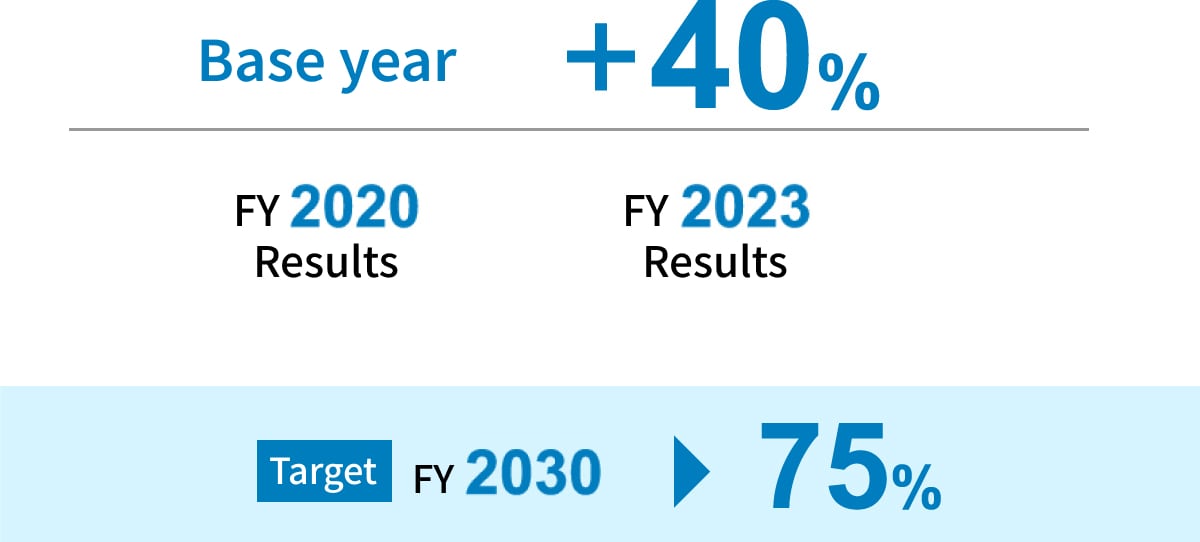

Ratio of ZEH to all new detached homes

To promote homes that contribute to carbon neutrality, in April 2023, we at Misawa Homes launched SMART STYLE Roomie, a standardized ZEH detached home. To promote ZEH, in April 2024, we added the "large roof type" and "single-story house type" to its lineup to support LCCM®, which is a future standard higher than ZEH.

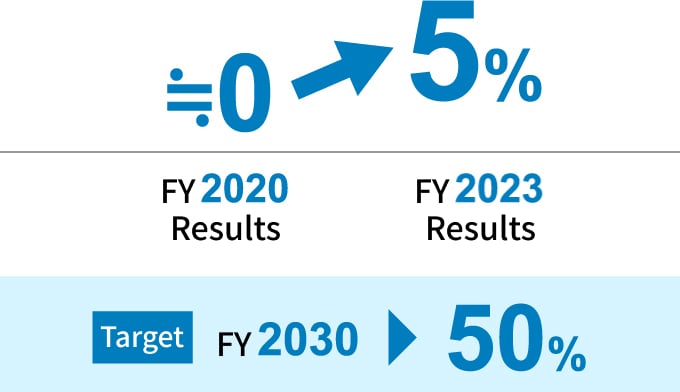

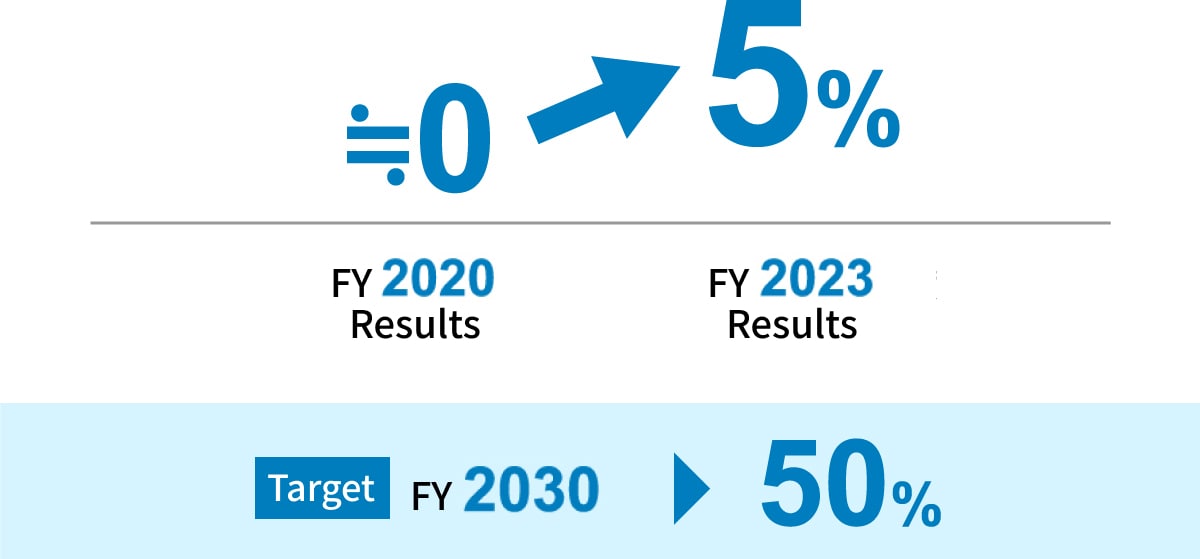

Ratio of ZEH-M (Nearly ZEH-M or higher) to all apartment buildings

Our efforts previously focused on detached homes. However, since the declaration of carbon neutrality goals, we have gradually gained some results even from low-rise apartment houses introducing ZEH-M and Nearly ZEH-M. Going forward, we will further strengthen the initiatives.

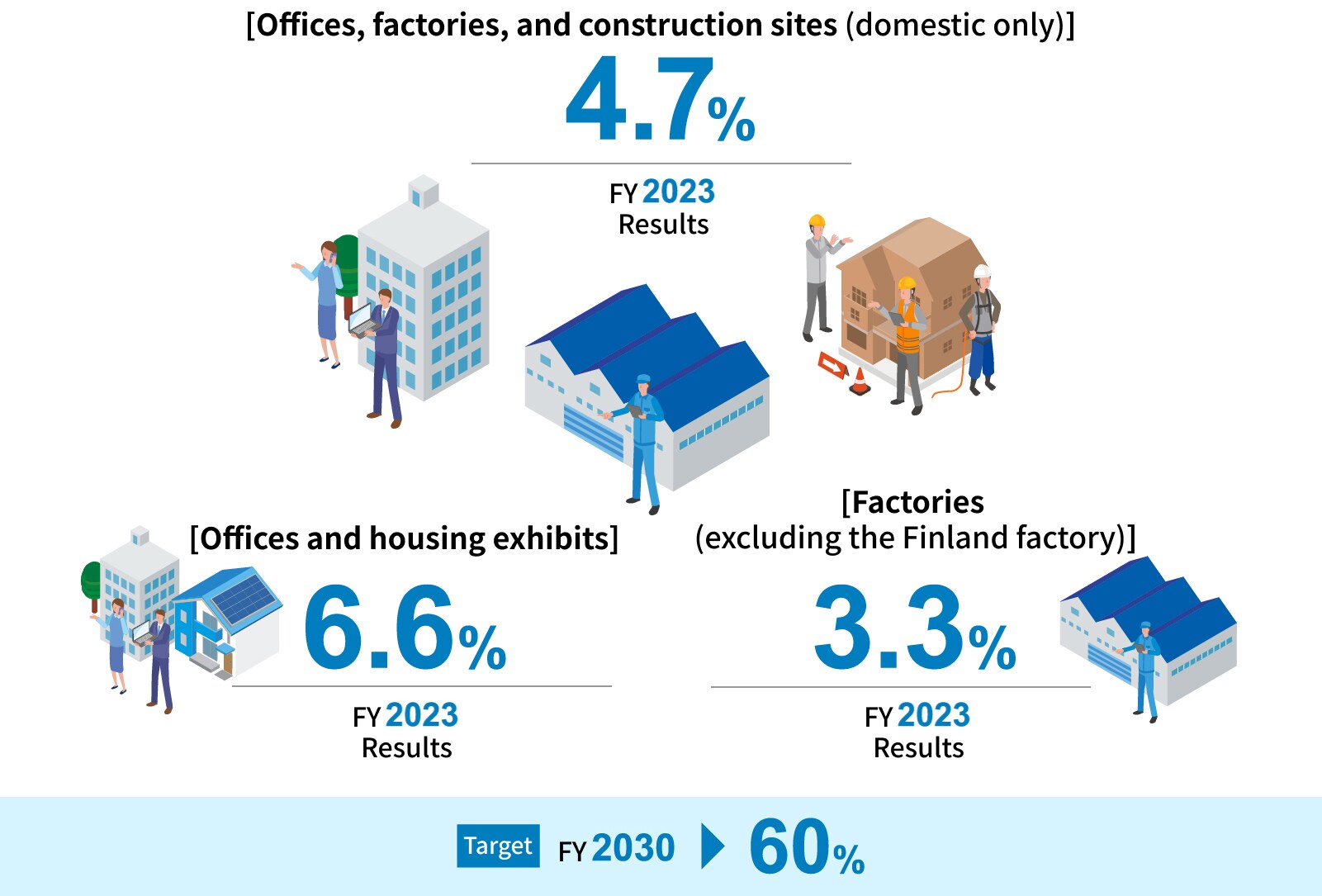

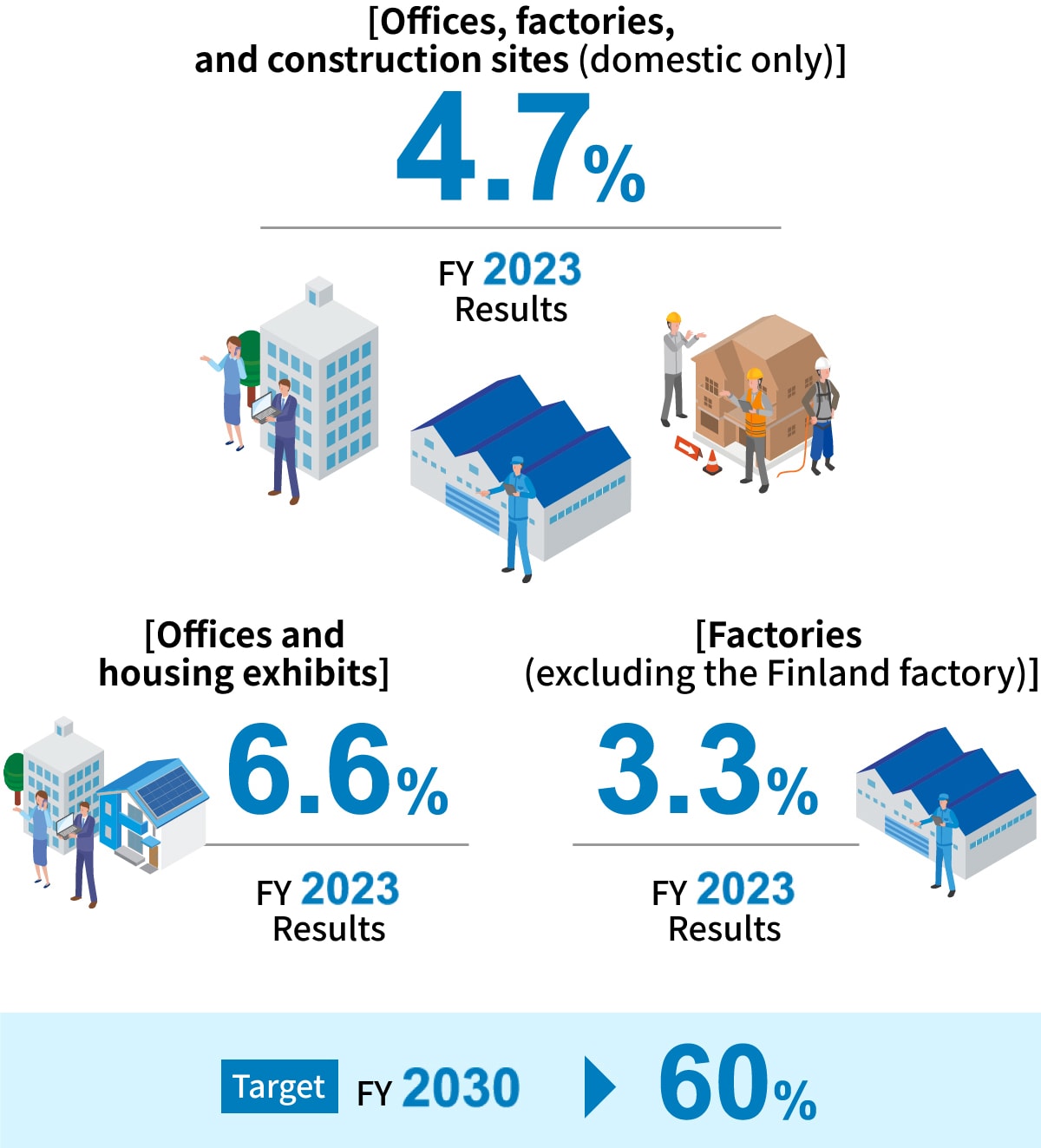

Renewable energy ratio

Reduction by Eco Reform

Eco Reform reduces CO2 emissions from households by improving window insulation, replacing with energy-saving products such as high-efficiency water heaters and Ene Farm, and renovating such as installation of a solar energy generation panel. The number of insulation or energy-saving renovations is expected to help progress toward carbon neutrality.

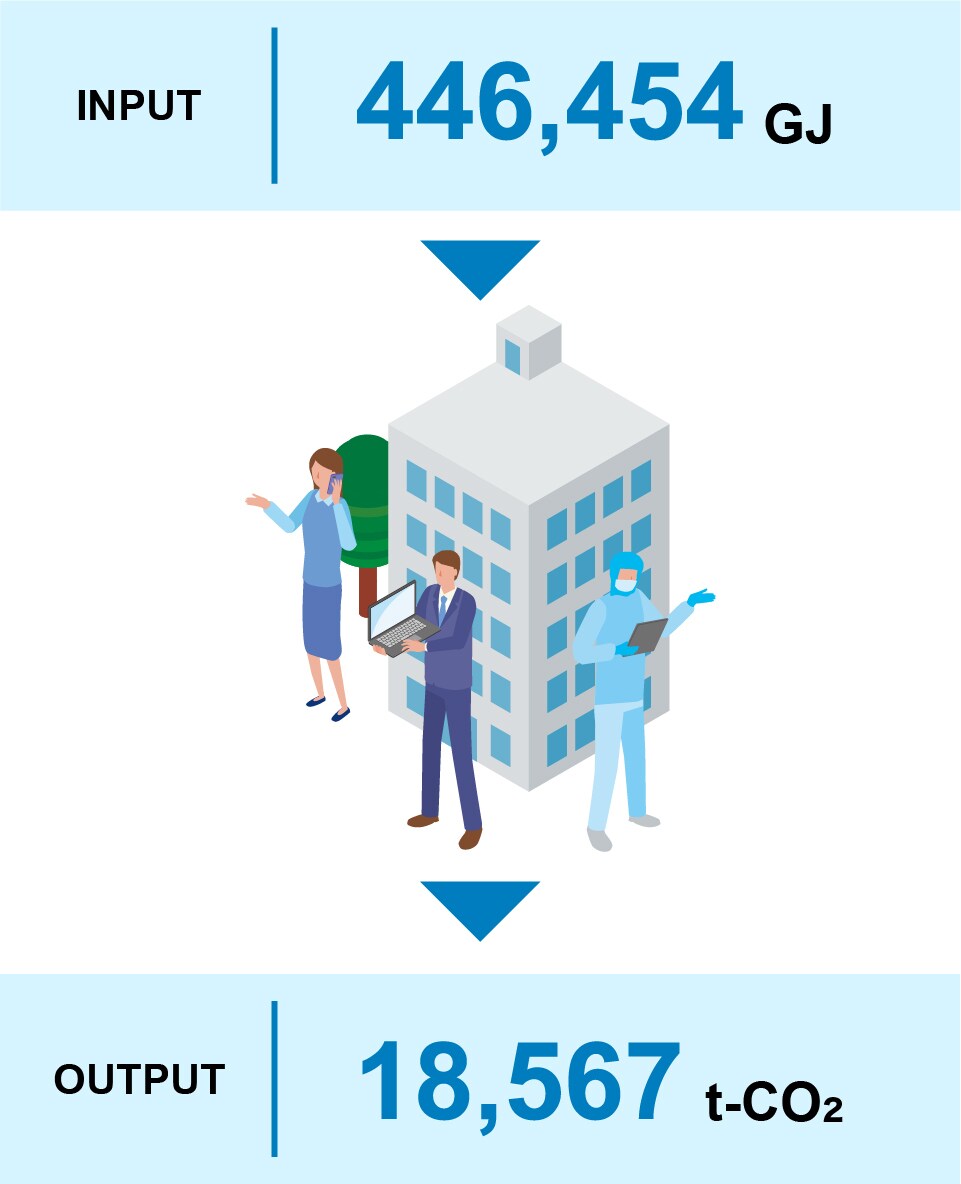

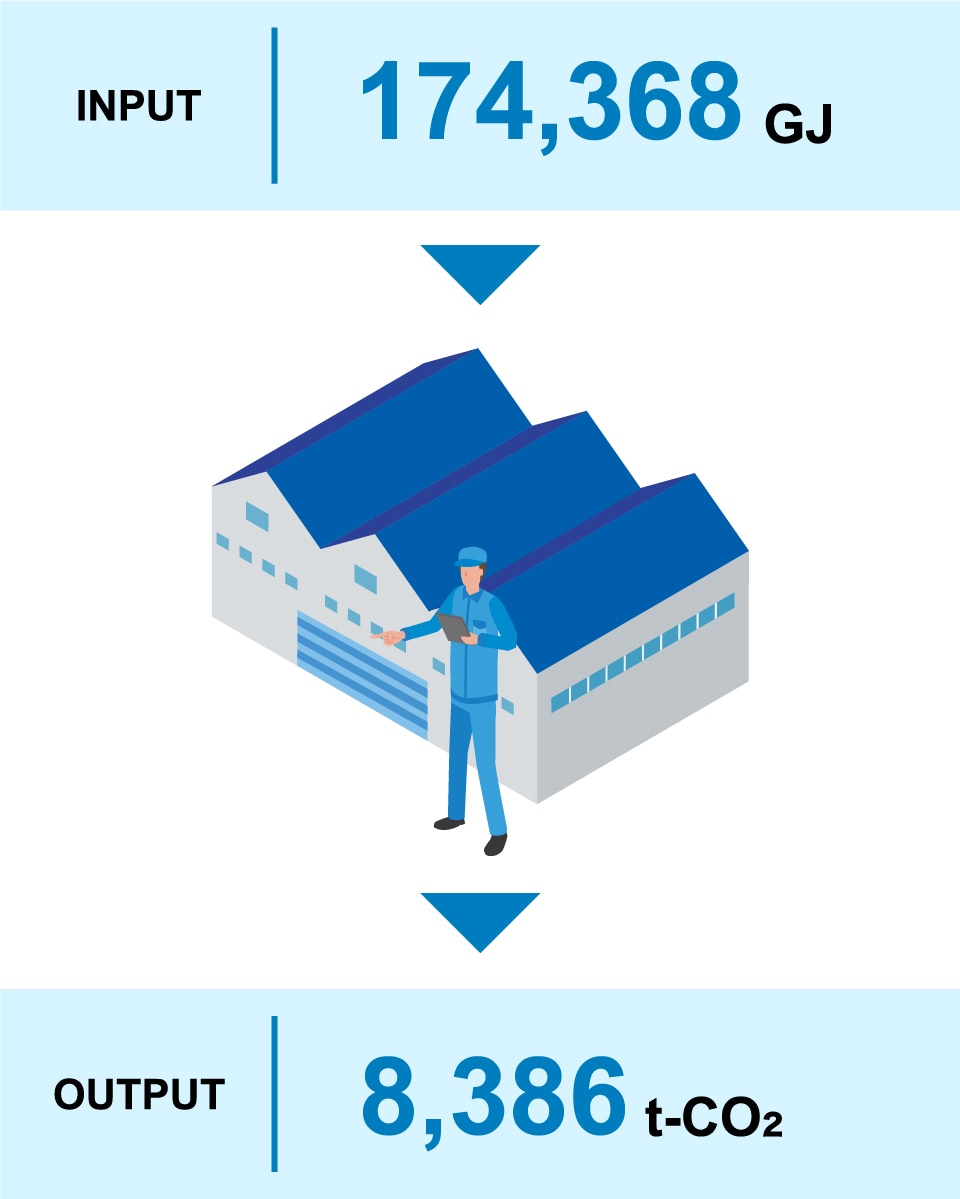

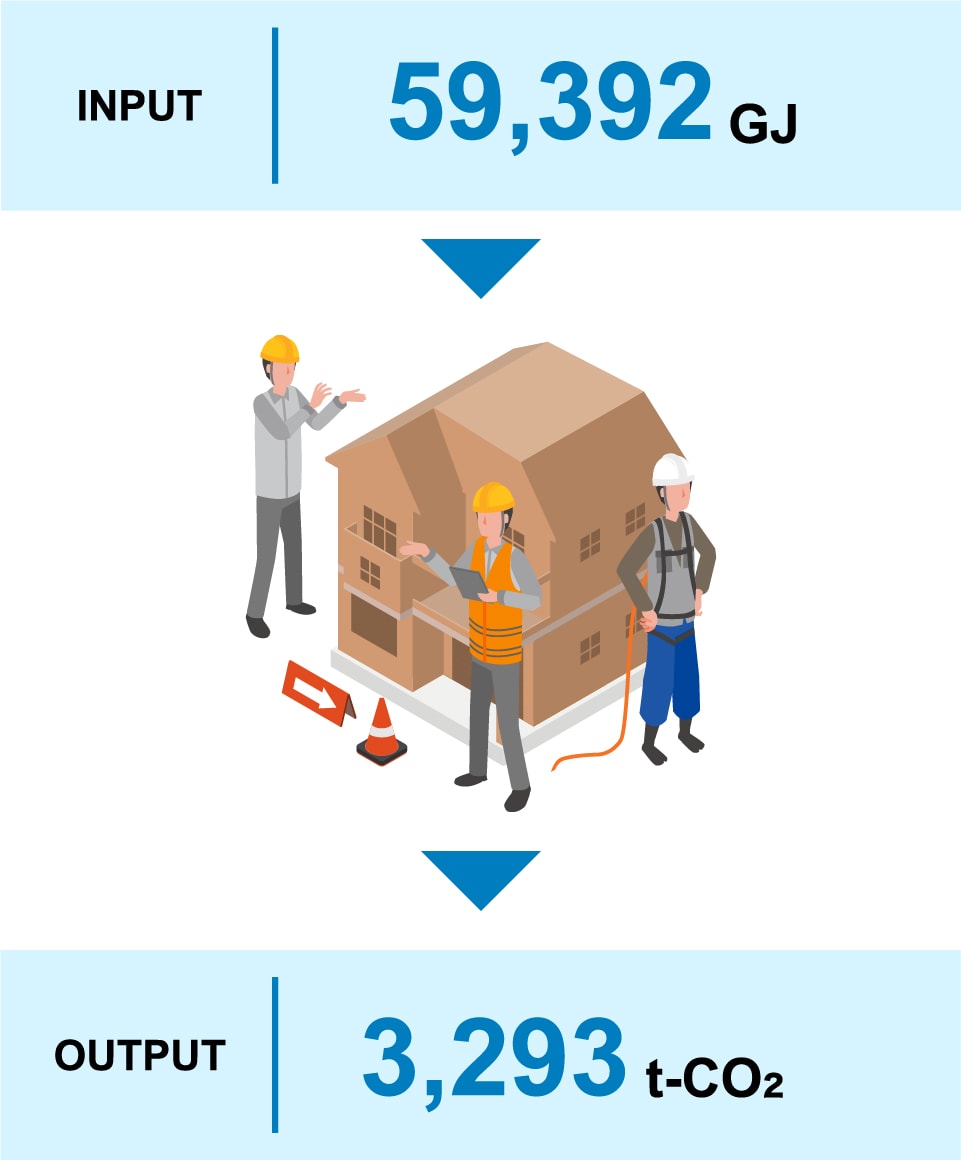

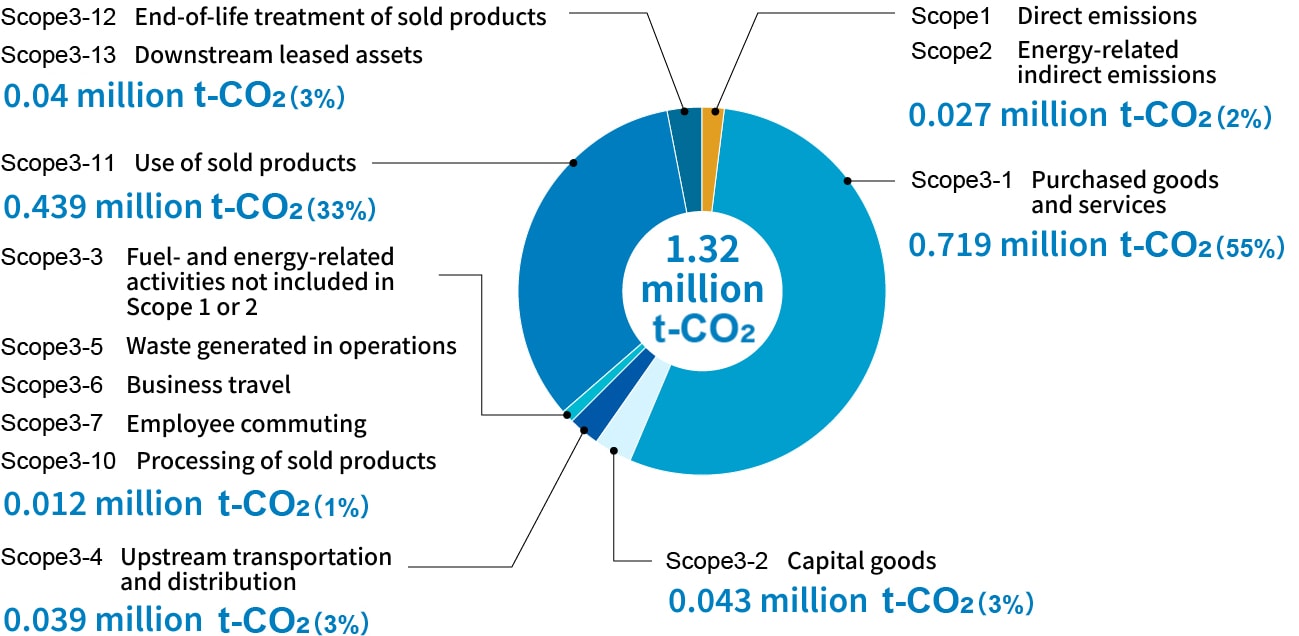

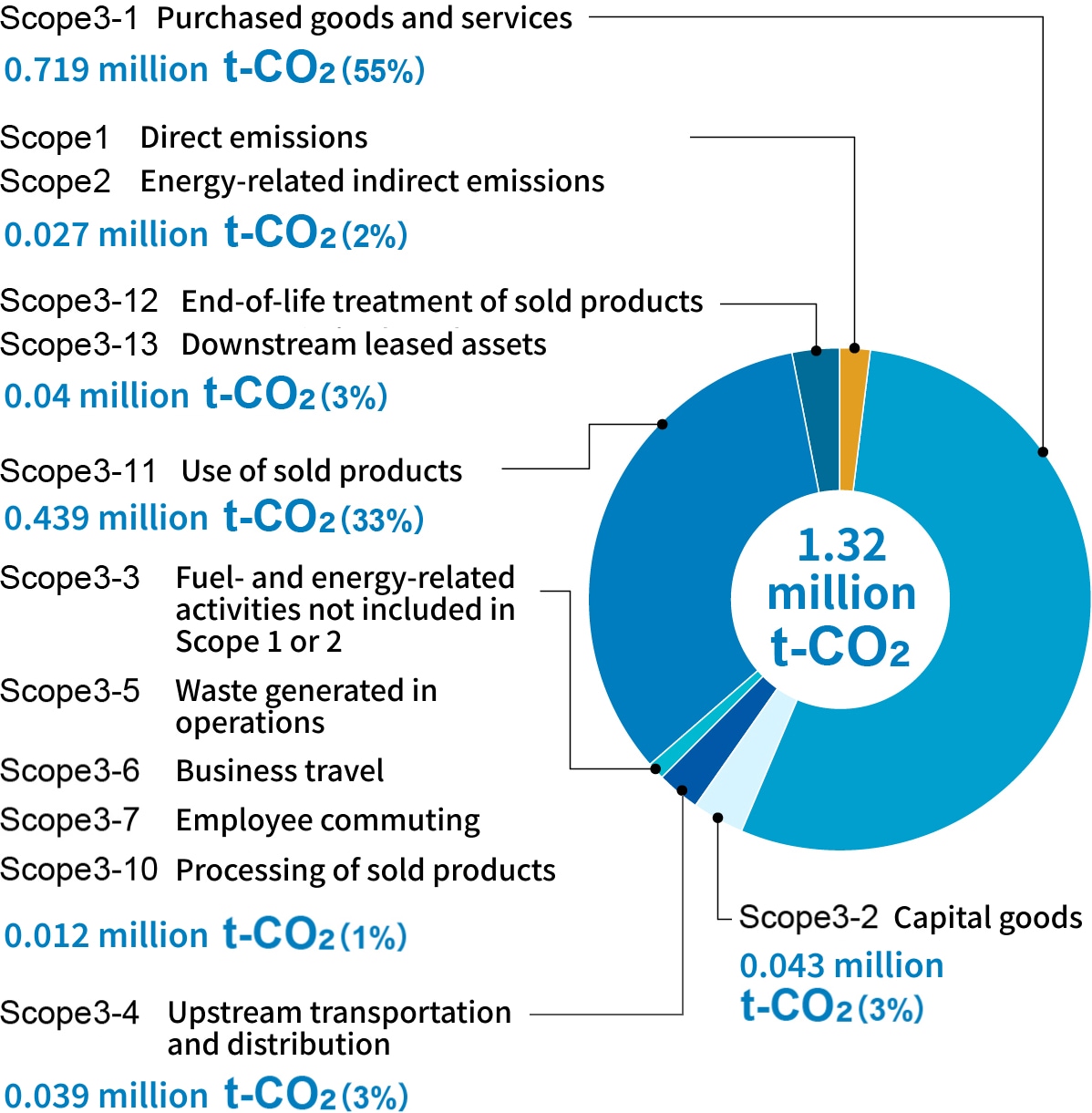

Calculated Greenhouse Gas Emissions through Supply Chains (Excluding Overseas and Community Development Businesses)

| Category | Definition | |

| Scope1 | Direct emissions | Direct emissions from the use of fuel and industrial processes by the reporting company (gasoline, light oil, kerosene, gas, etc.) |

| Scope2 | Energy-related indirect emissions | Indirect emissions from the use of electricity and heat purchased by the reporting company |

| Scope3—Category1 | Purchased goods and services | Emissions from activities up to manufacturing of raw materials, parts, purchased goods, sales-related materials, etc. |

| Scope3—Category2 | Capital goods | Emissions from construction and manufacturing of the reporting company's capital goods (tangible fixed assets such as buildings and facilities) |

| Scope3—Category3 | Fuel- and energy-related activities not included in Scope 1 or 2 | Emissions from procurement of fuel used in power generation, etc., or electricity and heat procured from other entities |

| Scope3—Category4 | Upstream transportation and distribution |

(1) Emissions from distribution (transportation, handling, and storage) of purchased products or services from the suppliers to the reporting company (2) Emissions from distribution services (transportation, handling, and storage) other than (1) (emissions from distribution paid by the reporting company) |

| Scope3—Category5 | Waste generated in operations | Emissions from transportation and processing of waste generated by the reporting company (for each product) |

| Scope3—Category6 | Business travel | Emissions from business travel by employees |

| Scope3—Category7 | Employee commuting | Emissions from transportation of employees when commuting to and from the place of business (for each city or business) |

| Scope3—Category8 | Upstream leased assets | Not applicable |

| Scope3—Category9 | Downstream transportation and distribution | Not applicable |

| Scope3—Category10 | Processing of sold products | Emissions from processing of intermediate products by the reporting company (emissions by non-consolidated dealers during construction and construction area) |

| Scope3—Category11 | Use of sold products | Emissions from use of products by users (consumers and companies) (design primary energy consumption) x years of use (60 years) |

| Scope3—Category12 | End-of-life treatment of sold products | Emissions from transportation and processing of products upon disposal by users (consumers and companies) (future demolition waste by each product) |

| Scope3—Category13 | Downstream leased assets | Emissions from operation of assets leased to other entities (rental property floor area x emission factor) |

| Scope3—Category14 | Franchises | Not applicable |

| Scope3—Category15 | Investments | Not applicable |